The Physical Reality of COVID-19 Supply Chains, Not the Virtual Kind

9 months to put a supply chain in place? Do me a favour...

Top consultancies cover COVID-19 supply chains

The top global consultancies had a lot to say about supply chains during COVID-19. As I was reading over a McKinsey’s assessment recently, titled ‘How COVID-19 is reshaping supply chains’, I discovered some interesting comment.

Their surveys of senior supply chain executives had revealed that there was an initial strong will to correct issues of product availability and supply chain complexity identified during COVID-19. The article reported, however, that short term measures, such as increasing inventories, had been favored over longer-term corrective strategies, such as regionalization or changes to complex, multi-tiered supply chains. This was neatly described in the article under the heading “It’s quicker to build inventories than factories.”

Indeed, it is, and the implication is that quick fixes were, and still are, being favored over genuine attempts to re-engineer global supply chains.

Life sciences companies reported few effects—really?

As well as the McKinsey article, I found another large consultancy account, this time authored by EY, titled How COVID-19 impacted supply chains and what comes next.

Chapter 1 was headed: The pandemic had substantial negative effects on supply chains—Certain sectors fared worse than others, but some life sciences companies reported few effects.

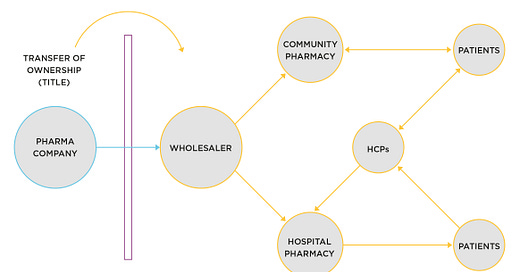

My ears pricked up when I read the news that life sciences companies reported few effects. How could that be when the life sciences and pharmaceutical sectors are the world’s most globalized in terms of supply chain architecture? Not only that, but the degree of outsourcing is off the scale, to the point where big pharma companies are now wholly reliant on contractors to get new drugs to market. I wrote about this for TrialSite News in May last year